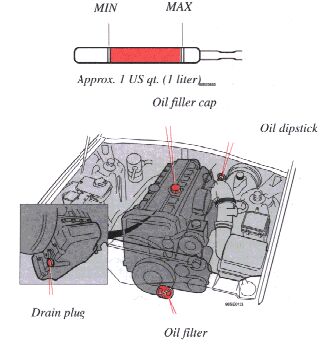

Checking the oil level

The oil level should be checked every time the car is refuelled.

This is especially important during the engine break-in period (up to the first service).

CAUTION : Not checking the oil level regularly can result in serious engine damage if the oil becomes too low. |

Be sure the oil level is maintained between the upper and lower marks on the dip-stick. Low oil level can cause internal damage to the engine and over-filling can result in high oil consumption. The distance between the dipstick marks represents approx. 1 US qt (1 liter) of oil.

Before checking the oil level after the car has been driven, park the car on a level surface and

wait at least 5 minutes

after the engine has been switched off. The oil level should be half-way between the MIN and MAX marks.

If the oil is checked before the car is driven (engine completely cold) the oil level should be at the MAX mark.

NOTE: The engine must be stopped when checking the oil.

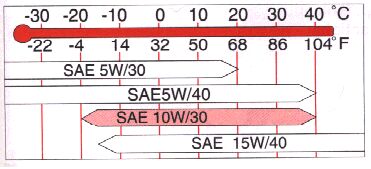

Draining the oil

Drain the oil after driving while it is still warm.

WARNING! The oil may be very hot. |

If you change the engine oil and filter yourself, your Volvo retailer can assist you in disposing of the used oil. Engine oil can be harmful to your skin - gloves should worn when performing this work.

To add or change engine oil

Add oil of the same kind as already used.

Capacity (including filter): 5.9 US qts = 5.75 liters.

Changing oil filter

Replace the oil filter at every oil change

WARNING! Oil spilled on a hot exhaust pipe constitutes a fire risk. |

pg. 8:7 Engine Oil, oil filter change interval |

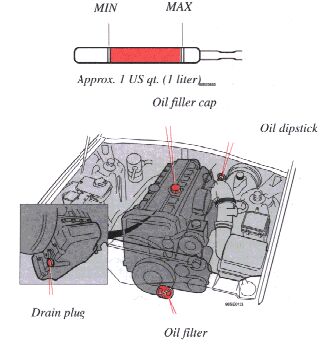

Oil quality

Meeting API specification SG, SG/CD, SH or ILSAC GF-1

For best fuel economy and engine protection consult with your authorized Volvo retailer for recommended oils. Oils with a different quality rating may not provide adequate engine protection.

Viscosity (stable ambient temperatures):

Do not use oils with other viscosity ratings. The use of incorrect viscosity oil can shorten engine life.

Volvo recommends the use of energy-conserving oils. Look for the API label. Synthetic oils complying with oil quality requirements are recommended for: driving in areas of sustained temperature extremes (hot or cold), when towing a trailer over long distances or for a prolonged driving in mountainous areas.

Extra oil additives must not be used unless advised by an authorized Volvo retailer.

SAE 15W/40 is recommended for use in driving conditions that raise oil temperature and increase oil consumption (i.e., mountain driving; trailer towing).

NOTE: SAE 15W/40 must not be used at low ambient temperatures; see viscosity chart.

Changing oil and oil filter

Oil and oil filter changes should be made as specified in the following table:

If driving conditions include: | Then the correct oil/oil filter change interval is: |

|

EVERY 6 MONTHS OR EVERY 5,000 miles= 8,000 km WHICHEVER COMES FIRST |

|

EVERY 12 MONTHS OR EVERY 10,000 miles = 16,000 km WHICH EVER COMES FIRST |

Torque exhaust and intake manifold nuts

A loose manifold could alter air/fuel ratio and cause an increase in emissions and/or poor driveability.

Air cleaner

Replace the air cleaner cartridge with a new one every 30,000 miles (48,000 km). The cartridge should be replaced more often when driving under dirty and dusty conditions, The filter cannot be cleaned and, therefore, should always be replaced with a new one.

Vacuum fittings, hoses and connections

Unstable idle, misfiring, or poor emission control is often caused by leaking vacuum hoses or connections. Check hoses and connections on distributor vacuum unit, connections on heater control servo systems and hydraulic brake servo.

Checking and adjusting idle air control system

Your Volvo is equipped with an electronically-controlled idle air control system that requires no checking or adjustment.

Fuel system cap, tank and lines, and connections

The effectiveness of the fuel system to contain hydrocarbons is dependent largely on a leakfree system. Check for proper sealing of gasoline filler cap which contains "0" ring-type seals. Check all evaporative hoses in vehicle for tightness. Check fuel lines under vehicle and repair if necessary.

Fuel (line) filter

The fuel line filter is located next to the fuel pump. This filter should be replaced every 100,000 miles (160,000 km). The filter is replaced as one complete unit.

Replace more frequently if contaminated fuel is introduced into the tank (or if there is reason to suspect that this has occurred).

Timing gear belt

Volvo recommends that the timing belt be replaced every 70,000 miles (112,000 km).

Exhaust Gas Recirculation (EGR)

This system operates by returning some of the exhaust gases to the engine to be recombusted: since this lowers the combustion temperature the amount of nitrogen oxides released into the atmosphere is reduced.

The EGR valve should be cleaned at 100,000 miles (160,000 km) and thereafter cleaned every 20,000 miles (32,000 km).

pg. 8:9 Servicing |

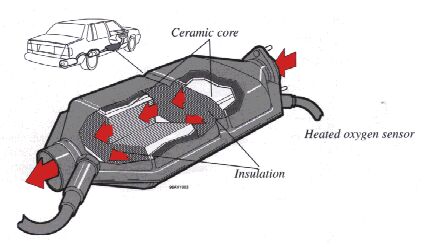

Three-way Catalytic Converter

This is a supplementary device in the exhaust system, designed to clean exhaust gases. This device is mainly a container with a ceramic material insert, designed to let the exhaust gases pass through channels in the insert. The channel walls are covered by a thin layer of platinum-palladium. These metals act as catalysts, permitting a chemical action to occur without actually taking part in it. The emission (CO, HC, NOx) content will increase if the three-way catalytic converter is damaged. Vehicles equipped with heated oxygen sensors use three-way catalytic converters containing platinum and rhodium.

CAUTION:

|

pg. 8:10 Servicing |

Multiport Fuel Injection System (MFI)

MFI is all-electronic and microprocessor-controlled. It can continually compensate for variations in engine load, speed and temperature to give the best economy and power. An important feature of the system is a mass air flow sensor that measures the mass of the inducted air instead of the volume. In this way the system can make instantaneous adjustments for changes in air temperature or density, thus always assuring the best economy with the lowest possible exhaust emissions.

Heated oxygen sensor

This is an emission control system designed to reduce emissions and improve fuel economy. The heated oxygen sensors monitor the composition of the exhaust gases leaving the engine. The exhaust gas analysis is fed into an electronic module. This adjusts the air-fuel ratio to provide optimum conditions for combustion and efficient reduction of the three major pollutants (hydrocarbons, carbon monoxide and oxides of nitrogen) by a three-way catalytic converter.

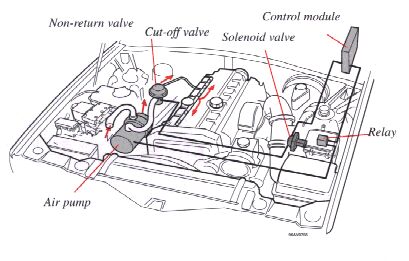

Air pump system

During cold starts, an electric pump is activated which directs air to the exhaust channels. This initiates a secondary combustion of exhaust gases which helps maximize hydrocarbon and carbon monoxide levels and reduces warm-up time for the three-way catalytic converter. The pump begins to function when the engine is started. It remains in operation until the three-way catalytic converter has reached normal operating temperature. A sound may be audible from the air pump during this warm-up period. This is normal. When idling, the air pump performs a self-diagnosis. A soft whining noise can be heard, which is also normal.

pg. 8:11 Servicing |

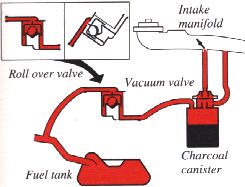

Evaporative control system

The car is equipped with a gas evaporative control system, which prevents gasoline fumes from being released into the atmosphere. The system is comprised of an expansion chamber in the fuel tank, a roll-over valve on the cross-member in front of the fuel tank, and a charcoal canister with built-in vacuum valve under the left-front wheel housing. The components are interconnected by hoses which channel fuel vapor from the gas tank to the charcoal filter, where it is stored until the engine is started and then drawn into the engine's fuel induction system.

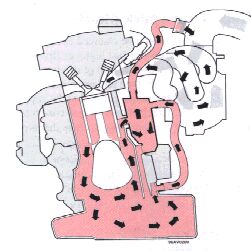

Crankcase ventilation

The engine is provided with positive crankcase ventilation which prevents crankcase gases from being released into the atmosphere. Instead, the crankcase gases are admitted to the intake manifold and cylinders.

PCV system

The orifice nipple in the intake manifold and the filter at the end of the PCV hose in the aircleaner should be inspected every 60,000 miles (96,000 km). Check/replace rubber hoses at the same time.

pg. 8:12 Servicing |

Replacing spark plugs

The spark plugs should be changed every 30,000 miles (48,000 km). However, city driving or fast highway driving may necessitate changing after 15,000 miles (24,000 km) of driving. When installing new plugs, be sure to fit the right type and use correct torque, see Specifications. When changing the plugs, check that the suppressor connectors are in good condition. Cracked or damaged connectors should be replaced. When changing the spark plugs, clean the terminals and the rubber seals.

CAUTION: Do not use silicone-based lubricants, which can have adverse effects on electrical components. |

WARNING!

|